+91 97129 87467

sales@vijimech.com

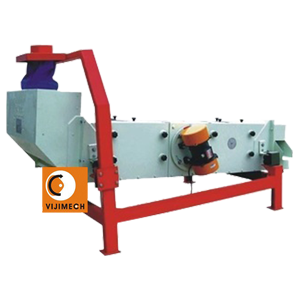

ULTRASONIC VIBRO SCREEN

Introduction

Vijimech Ultrasonic Vibrating Screen is used to separate fine powders that are not effectively sieved by normal vibrating screens.

Very fine powders end up chocking the screen in conventional sieving method.

Such powders require High frequency arrangement to overcome this issue.

At high frequency the powder behaves as fluid and is easily sifted through the screen / wire-mesh.

Working Principle

Ultrasonic vibrations are generated by a suitable transducer that generates high frequencies.

This transducer device that is attached on the vibrating surface eventually transfers ultra high frequency vibrational energy.

This high frequency makes the particle pass through the screen in fluid way.

Ultrasonic vibrating screen is usually used in screening superfine powder where the ordinary vibrating screen cannot perform.

Features

It performs well in high adsorption, easy clustering, high static, high precision, high density, light proportion, etc.

It performs well in separating micro particles of similar size.

The sifting is done at ambient temperature.

Application

It has prominent advantages in solving materials sieving problems such as high absorption, easy agglomeration, high static, high precision degree, light weight, etc. And it is widely used in size classification, product reclamation, screening and liquid cleaning.

Industries where it is used

Chemical industry: resin, pigment, cosmetic, coatings, medicine powder Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder, sauce, syrup Metallurgy and Mine industry: aluminium powder, copper powder, ore alloy powder, welding rod powder, Medicinal industry: all kinds of medicine Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon