+91 97129 87467

sales@vijimech.com

ABRASIVE MEDIA

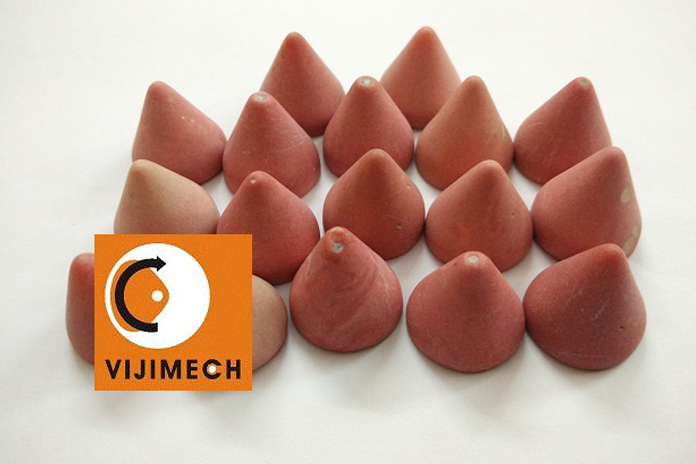

Ceramic Media

Ceramic media is recommended for general purpose polishing, light and heavy deburring, fast and extra fast deburring and ultra aggressive metal removal. Ceramic media is best for heavy cutting and hard metals. Ceramic media supports very heavy parts better than plastic media.

We also offer Steel media and Plastic media as per the requirement

Different types of Media are Available

Different types of Media are Available

Plastic Media

Plastic media is recommended for general metal removal, pre-painted or pre-plated finishing, polishing, and fast and heavy cutting. Plastic media is used for soft metals (such as brass and aluminum) or stringy materials to avoid rolling the burr over into a hole. Plastic media produces a very smooth finish, but very little shine.

Plastic media is safe for parts with threads and is good for preparing parts for anodizing. The tetrahedron and cone shapes are good for parts with holes. The triangle shape is good for corners and flats. Combinations of plastic media can be used to process geometrically complex parts

Different types of Media are Available

Steel Media

Round spherical steelballs, spheres, eclipses - flat end balls, satellites, ballcones, diagonals, beveled cylinders and pins are the various shapes of steel media which are offered . These are used in mass finishing processes for burnishing, metal polishing, mirror finishing, tumbling, eliminating manual buffing and pre-plate applications.

The media are run in vibratory and mass finishing equipment along with compatible chemical compounds

Corn Cobb

Corn cob media is used in dry finishing processes. Its lighter weight makes it the ideal media for adding a finishing shine to your parts. Corn cob media is often used in the final stage of a deburring process.